Which Two Control Charts Are Always Used Together

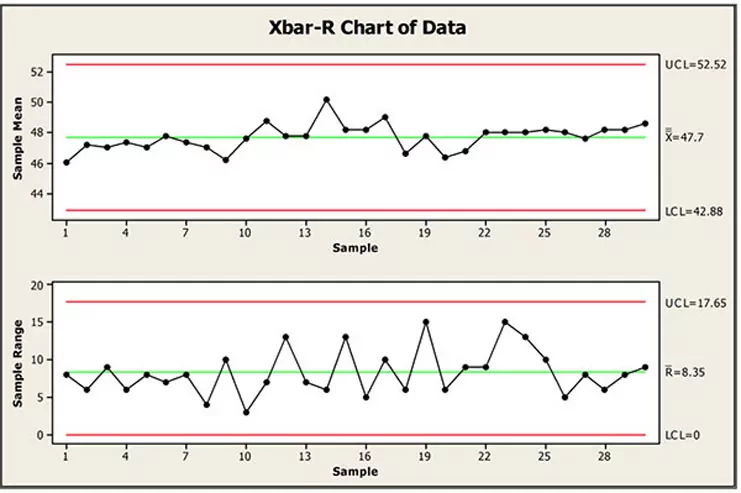

This pairing allows you to study the variation between data points X-Bar graph AND the variation within a subgroup range graph. Traditional control charts are mostly designed to monitor process.

Difference Between X Bar And R Chart And How They Are Used Rop

It is necessary to detect is there any departure from the usual state of affairs.

. Most widely used control chart is the Shewhart X-chart which should be used together with an R-chart an S-chart or an S2-chart. What we do is simply a procedure. Control Charts for Continuous Data Two charts Charts of Value or Sample Mean XChart plots an individual value Xbar Chart plots the sample average Charts of Variation-S average standard deviation MR chart plots the moving range of the individual values S chart plots the standard deviation of the sample.

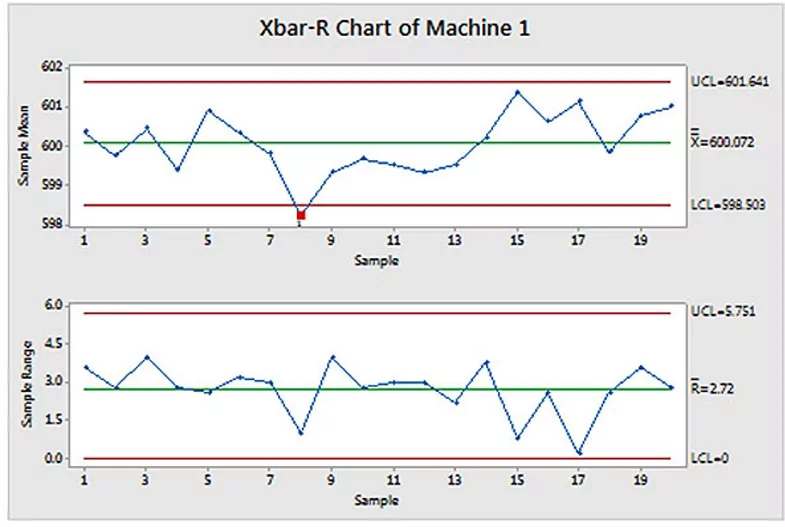

These are often refered to as Shewhart control charts because they were invented by Walter A. The standard chart for variables data X-bar and R charts help determine if a process is stable and predictable. Which two control charts are typically used together.

Hence at any instant of time a process status may be interpreted as in control or out of control. These lines are determined from historical data. The first referred to as a univariate control chart is a graphical display chart of one quality characteristic.

The X-bar chart shows how the mean or average changes over time and the R chart shows how the range of the subgroups changes over time. This visual picture of your process makes it easy to see where the process could potentially. When properly set up these charts quickly detect large changes in.

Shewhart understood that no matter how well a process was designed there will always be. Control charts are used to routinely monitor quality. The second referred to as a multivariate control chart is a graphical display of a statistic that.

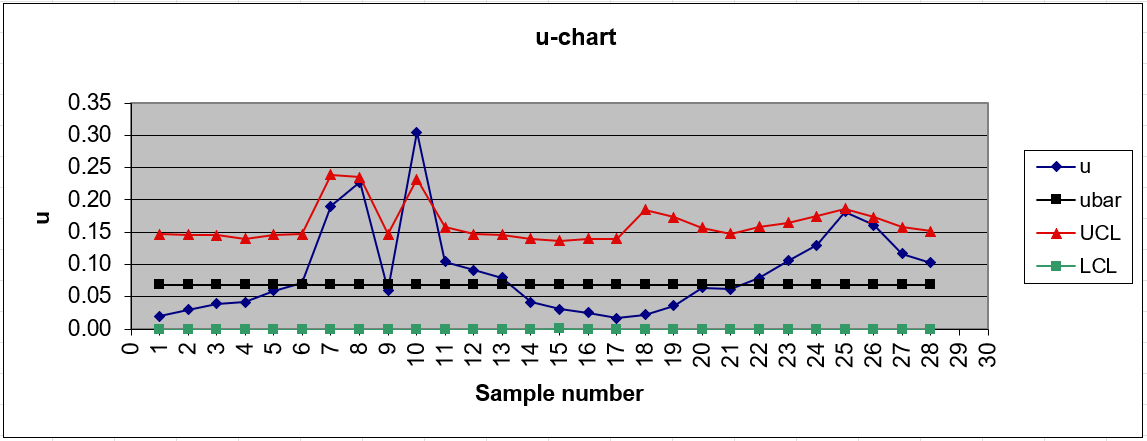

If the variable such as lea strength lap weight CSP etc is assumed as θ a. Invented by Walter A. C Control Chart is used when there is more than one defect and the sample size is fixed.

Control Charts Control Charts are use to distinguishes between specializes or common-cause of variation that Is present In a process. Shewhart introduced these charts in 1924 as simple tools to be used by workers in production lines. It may be to fill out a cost sheet check a person in a hospital drive to work fill a prescription etc.

One set that monitors each batch during its course of operation. The X-Bar Chart is typically combined with an R-Chart to monitor process variables. You can see that mean and range charts are used to monitor different variables.

While U Control Chart is used for more than one defect and if the sample size is not fixed. The mean or x -bar chart measures the central tendency of the process whereas the range chart measures the dispersion or variance of the process. But on top of that the methods produce results.

And a second control chart that plots the average batch parameter for all batches as an Individual data value. If either chart indicates a potential change in the process the process is stopped and investigated for the cause. There are two main categories of control charts.

Depending on the number of process characteristics to be monitored there are two basic types of control charts. Up to 5 cash back Using Mean and Range Charts Together. Control charts also known as Shewhart charts or process-behavior charts are a statistical process control tool used to determine if a manufacturing or business process is in a state of control.

For example the X-Bar R Range Chart pairs together a control chart for X-Bar Average with a control chart for the Range R of the data. Control charts dont work everywhere - just in the vast majority of processes. In spite of their simplicity these charts turned out to be highly efiective in practice.

Shewhart while he was working for Bell Labs in the 20s control charts have been used in a variety of industries as part of a process improvement methodology. Since both variables are important it makes sense to monitor a process using. An X-bar and R range chart is a pair of control charts used with processes that have a subgroup size of two or more.

OM Chapter 13 hw. Control charts are the foundation of statistical process control SPC after all. Check all - range chart - c chart - mean chart - p chart - range chart.

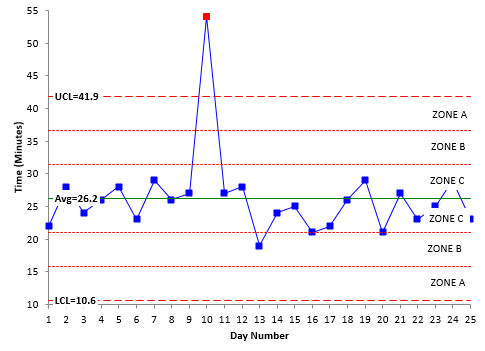

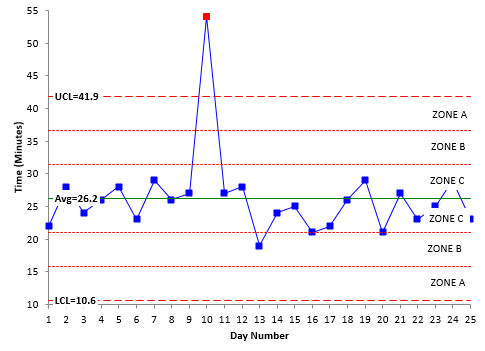

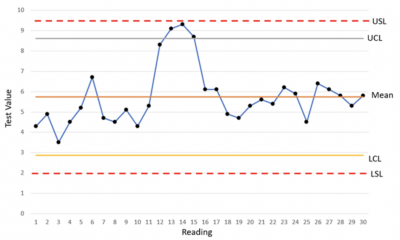

If the variable isnt under control then control limits might be too general which means that causes of variation that are affecting the process mean cant be pinpointed. A control chart always has a central line for the average an upper line for the upper control limit and a lower line for the lower control limit. It is more appropriate to say that the control charts are the graphical device for Statistical Process Monitoring.

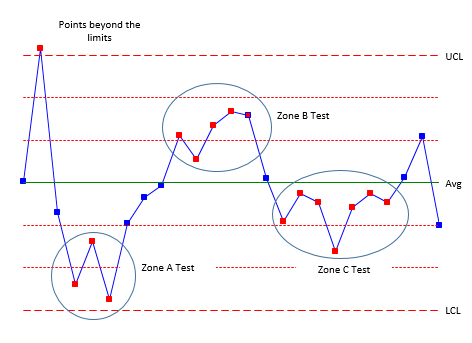

Within these two categories there are seven standard types of control charts. Selection of the right Control Chart. The use of detection rules results in the control chart becoming an operational definition of a stable process.

The basis of the control charts are 3σ limits with an assumption the experimental date is normally distributed. Detection rule 1. A point that falls beyond a process limit control limit.

Donald Wheeler those who do not use control charts will always be at a disadvantage to those who do. Thus two kinds of control charts are used together. Variable control charts for measured data.

There are two basic types of control charts- Variables Quantitative data Measured Attributes Qualitative data Counted Variable Control Charts Use actual measurements for charting Types- Average Range charts Median. One to track the process mean and the other to track the process range or standard deviation two ways to measure variability. The process mean is the center line and if this isnt specified then its.

A Key Tool for Ensuring Quality and Minimizing Variation. In this latter control chart the Moving Range chart is used to monitor the between batch variation. What got my attention was the misinformation about control charts in the blog - things like control limits are confidence limits a spike above two standard deviations is an out of control point that a control chart is used to keep a process at average etc.

Special consolidation warehouses are used when shipments from various sources are pulled together and combined into larger shipments with a common destination. In cases like these it is best to maintain two sets of control charts. Attribute control charts for counted data.

By comparing current data to these lines you can draw conclusions about whether the process variation is consistent in control or is unpredictable out of control affected by special. All of those processes yield a production-either a commodity or a service. If you are not sure where a control chart can be used in your process start by making a process flow diagram of your process.

Shewhart who worked for Bell Labs in the 1920s. Each point on the chart acts as a subgroup mean value. Herein two detection rules are applied to find the unnatural patterns which are the signals of instability in the process.

As you may have seen Control Charts are also commonly paired together. Sets with similar terms.

Using Control Charts To Detect Common Cause Variation And Special Cause Variation Minitab

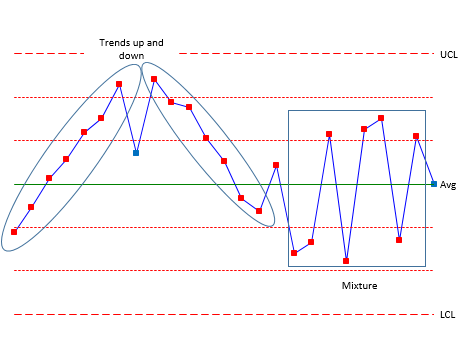

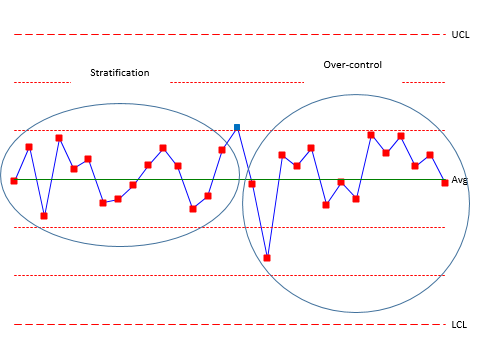

Control Chart Rules And Interpretation Bpi Consulting

Pin On Lightningchart Js Fastest Javascript Charts

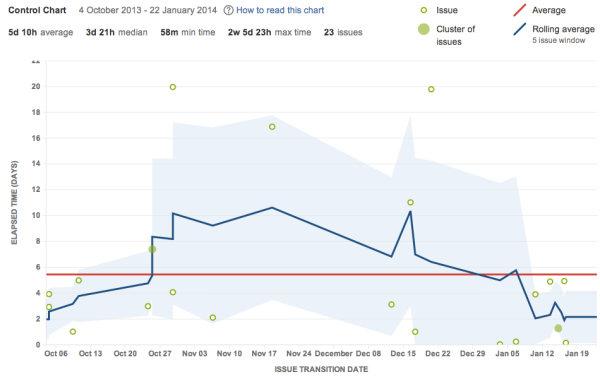

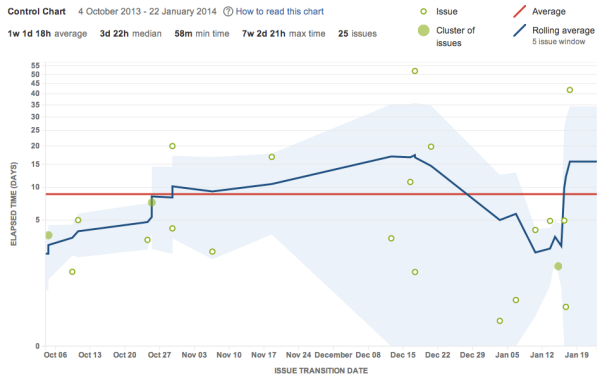

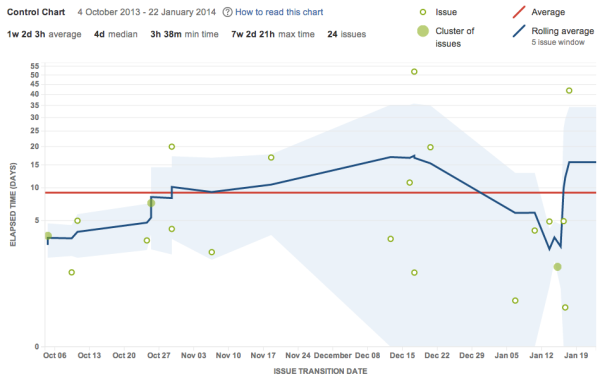

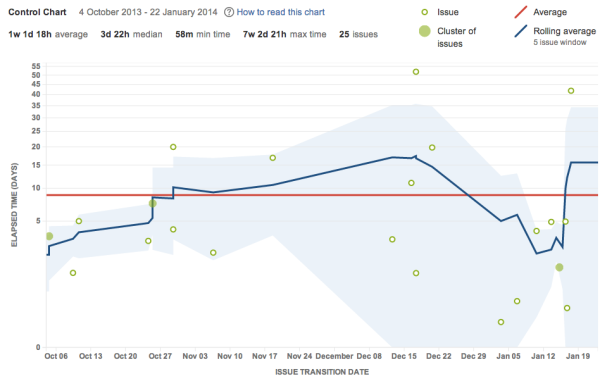

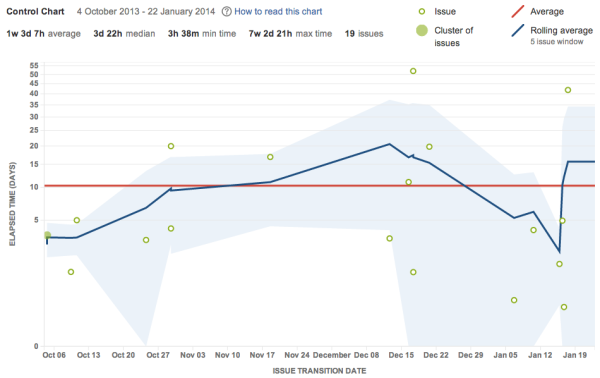

View And Understand The Control Chart Jira Software Cloud Atlassian Support

Upper Specification Limit Usl Definition

View And Understand The Control Chart Jira Software Cloud Atlassian Support

View And Understand The Control Chart Jira Software Cloud Atlassian Support

Attribute Control Chart Statistics How To

Tqm And Quality Control Processes Process Control Statistical Process Control Change Management

I Love Eric Johnson Strat Wiring Page 2 Guitar Pickups Luthier Guitar Strat Guitar

View And Understand The Control Chart Jira Software Cloud Atlassian Support

Control Chart Rules And Interpretation Bpi Consulting

Control Chart Rules And Interpretation Bpi Consulting

Control Chart Rules And Interpretation Bpi Consulting

View And Understand The Control Chart Jira Software Cloud Atlassian Support

Difference Between X Bar And R Chart And How They Are Used Rop

Using Control Charts To Detect Common Cause Variation And Special Cause Variation Minitab

25 Best Powerpoint Ppt Chart Graph Templates For Data Presentations For 2020 Powerpoint Charts Powerpoint Tutorial Powerpoint Chart Templates

Comments

Post a Comment